Polymeric Antiscants for Sugar Evaporators

Sugar Processing

Carboxylate polymers are one of the important and key raw materials to be used in industrial water treatment like boiler, cooling circuits, RO plants, desalination and in sugar evaporators etc. These polymers are used for scale prevention and dispersants of insoluble solids for water treatment industry. We manufactures various carboxylate polymers like homopolymer, copolymer, terpolymer, multipolymer and polymaleic acid for antiscalant application. These polymers are synthesised in a fully automatic plant through precisely control process to provide optimum inhibitions. Apart from supply our application team not only ensures the performance of each and every material but also provides technical assistance to our customers regarding application of the product and formulations.

Synonyms : Polyacrylic Acid (PAA) 50%, Polymaleic Acid (PMA), Acrylic Acid-2-Acrylamido-2-Methylpropane Sulfonic Acid Copolymer (AA/AMPS), Sulphonated Polyacrylic Acid Copolymer, AA-AMPS copolymer, acrylic acid sulphonated copolymer, acrylic acid terpolymer, acrylic polymer in primary form, acrylic acid homopolymer, acrylic acid copolymer, Polyacrylic acid

Description

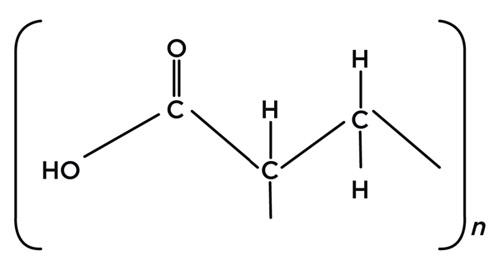

These polymers are low molecular weight acrylic acid homopolymers. They have got very good dispersing & scale inhibiting properties hence can be used very effectively in industrial water treatment, boiler water treatment etc. These products are synthesized by uniquely developed process to have better control over molecular weight of the polymers. So also the process produces polymers with narrow distribution of molecular weight making the polymers more effective & cost efficient.

Application

Specification

| Parameter | Index | |

|---|---|---|

| Appearance | Colorless to pale yellow, clear liquid | Colorless to pale yellow, clear liquid |

| Total Solid (%) | 47 – 49 | 47 – 49 |

| Avg. Mol. Wt. (Aprx.) | 4500 | 2000 |

| Sp. Gravity | 1.2-1.3 | 1.2-1.3 |

| pH | 3 - 4 | 3 - 4 |

(These are typical values and not specifications)

Packing

Tanker Load, 1250 kg in IBC & 250 Kg barrels

Description

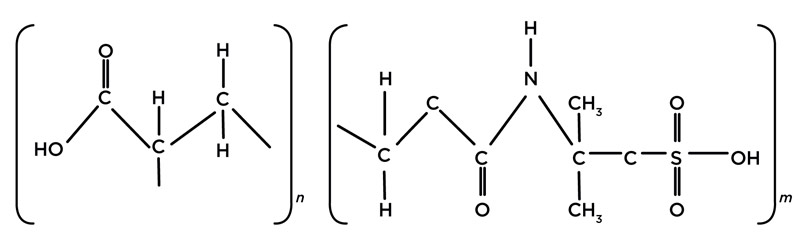

These are low molecular weight acrylic acid & 2- acrylamido -2 –methylpropanesulphonic acid co-polymers. These polymers provides a unique combination of two different polarities a weakly anionic carboxylate group which provides effective dispersion and scale inhibition action & a strongly anionic sulphonated group offers high water hardness and iron tolerance to the polymer. These polymers shows synergistic performance for scale inhibition when combine with organo-phosphates.

Application

These polymers can be used as Scale inhibitor and dispersing of insoluble salts in industrial Cooling circuits, oil filed industry.

Due to its high iron and zinc stabilization can be used as a iron oxide and zinc stabilizer. These polymers also can be used as phosphate scale inhibitors in various water based systems.

Specification

| Parameter | Specification | ||

|---|---|---|---|

| Appearance | Colorless to brown, clear liquid | Colorless to pale yellow, clear liquid | Colorless to pale yellow, clear liquid |

| Total Solid (%) | 43 – 45 | 42 – 44 | 35 – 39 |

| Avg. Mol. Wt. (Aprx.) | 4500 | 4500 | 11000 |

| Sp. Gravity | 1.2 – 1.3 | 1.2 – 1.3 | 1.1 – 1.3 |

| pH | 4 to 5 | 3.5 to 4.5 | 4 to 5 |

(These are typical values and not specifications)

Packing

Tanker Load, 1250 kg IBC & 250 kg barrel

Description

These are low molecular weight terpolymer. These polymers contain three different functionalities highly anionic sulphonated group, moderately anioninc carboxylter group and nonionic hydrophobic group. Due to these unique combinations the polymers shows very good stability and performance in a stress conditions like high temperature, high pressure and high hardness. So also shows excellent performance in presence of iron.

Application

These polymers can be used as Scale inhibitor and Dispersing of insoluble salts in industrial water treatments like Boilers, RO, evaporators etc. Ideal for use for desalination process.

Specification

| Parameter | Specification |

|---|---|

| Appearance | Colorless to pale yellow |

| Total Solid (%) | 42 – 44 |

| Avg. Mol. Wt. (Aprx.) | 4500 |

| Sp. Gravity | 1.15 – 1.25 |

| pH | 2 to 4 |

(These are typical values and not specifications)

Packing

Tanker Load, 1250 kg IBC & 250 kg barrel

Description

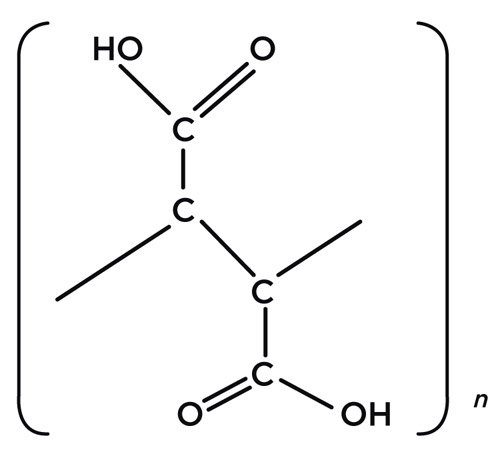

PMA is a low molecular weight maleic acid homopolymer synthesized by solvent route polymerization of maleic anhydride. The product is manufactured in specially designed automatic plant in order to obtain high level of consistency & reproducibility in the product quality. The process also ensures accurate control over molecular weight & narrow molecular weight distribution.

Application

PMA can be used in water treatment applications like RO, cooling tower, oilfield, sugar evaporators, desalination etc. PMA is used for Dispersing & Scale inhibitions of various salts like calcium carbonate, calcium silicate etc. Particularly useful in area of high hardness, high salinity, high alkanity and high silica content etc.

Specification

| Parameter | Specification |

|---|---|

| Appearance | Light yellow to amber, clear liquid |

| Total Solid (%) | 47 – 53 |

| Avg. Mol. Wt. (Aprx.) | 1000 |

| Sp. Gravity | 1.15 – 1.25 |

| pH | <2 |

(These are typical values and not specifications)

Packing

Tanker Load, 1250 kg IBC & 250 kg barrel

Description

This polymer is a low molecular weight maleic multipolymer and work as very good scale inhibitors and dispersant for variety of scales like calcium carbonate, calcium sulphates & oxalte etc. this polymer can be used to replace phosphonates like HEDP and maleic acid homopolymers as scale control agent.

Application

This polymer can be majorly used as dispersing agent and scale inhibitors in water based systems like cooling circuits & boilers. It shows much improved performance in calcium base scale inhibition compared to conventional acrylic homopolymer, maleic homopolymer and HEDP due to its selective combination of monomers.

Specification

| Parameter | Specification |

|---|---|

| Appearance | Pale yellow to light brown |

| Total Solid (%) | 39 – 41 |

| Avg. Mol. Wt. (Aprx.) | 2000 |

| Sp. Gravity | 1.2 – 1.3 |

| pH | 6 to 8 |

(These are typical values and not specifications)

Packing

Tanker Load, 1250 kg IBC & 250 kg barrel