Dispersing & Defloculating Agents for Ceramic & Tiles

Ceramic & Tiles

Our carboxylate polymers find application in ceramic industry, particularly in the wet milling process. In wet grinding process when particles are crushed in ball mill to breakdown into smaller particles the viscosity of the slurry increases due to formulation of new surface area these increasing viscosity affects the grinding process. Carboxylate polymer disperses the newly form clay particles and reduced the viscosity of the slurry and provide efficiency in milling process. These polymers provides multifold benefit in ceramic industry like :

- Offers high reduction in water this saves lot of time and cost in next spray drying process

- Reduce viscosity and stable dispersion of the slurry facilitates easy handling and storage of the slurry

- These polymers provide a cost effective replacement for sodium tripolyphosphate (STPP).

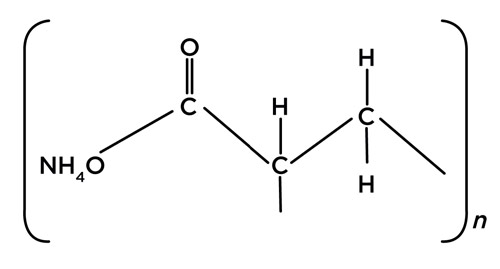

Synonyms : Polyacrylic Acid Sodium Salt (PAAS) 50%, Polyacrylate sodium, Sodium polyacrylate, aqueous dispersants, ceramic dispersants, Ammonium polyacrylates, Viscosity reducing agent, water reducing agent, grinding aid agent, dispersants, Carboxylate polymer, Maleic multipolymer

Description

This is a low molecular weight polymers with narrow distribution of mol. Wt. The polymer shows very good dispersing property particularly for inorganic pigments.

Application

Ammonium polyacrylate can be effectively used in ceramic and tile as ideal dispersing agents, viscosity reduction / grinding aid, water reducer. This polymer keeps the solids dispersed in various conditions providing very stable dispersions. By dispersing the particles they maintain good uniformity. When compared with other dispersing agents this dispersants provide very good storage stability of the solids. They are highly effective at a wide range of temperatures & ph.

Specification

| Parameter | Index |

|---|---|

| Appearance | Colorless to pale yellow, clear liquid |

| Total Solid (%) | 44 – 46 |

| Avg. Mol. Wt. (Aprx.) | 4500 |

| Sp. Gravity | 1.3 – 1.4 |

| pH | 6 to 8 |

(These are typical values and not specifications)

Packing

Tanker Load, 1250 kg in IBC & 250 Kg barrels.

Description

Carboxylate multipolymers are low molecular weight polymers can be used as primary dispersing agent.

Application

Carboxylate multipolymers can be effectively used in mineral grinding particularly in the manufacturing of ceramic and tile as ideal dispersing agents, viscosity reduction / grinding aid, water reducer. These polymers keep the solids dispersed in various conditions providing very stable dispersions. By dispersing the particles they maintain good uniformity. When compared with other dispersing agents these dispersants provide very good storage stability of the solids. They are highly effective at a wide range of temperatures & ph.

Specification

| Parameter | Index | |

|---|---|---|

| Appearance | Pale yellow to light brown, clear liquid | Pale yellow to light brown, clear liquid |

| Total Solid (%) | 39 – 41 | 39 – 41 |

| Avg. Mol. Wt. (Aprx.) | 50000 | 3000 |

| Sp. Gravity | 1.22 – 1.32 | 1.2 – 1.3 |

| pH | 7 to 9 | 7 to 9 |

(These are typical values and not specifications)

Packing

Tanker Load, 1250 kg in IBC & 250 Kg barrels

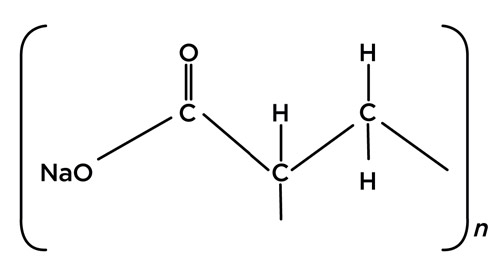

Description

These are low mol. Wt. sodium salt of acrylic acid homopolymer . Produced by special delayed addition process to yield narrow distribution of mol. Wt.

Application

PAAS can be used in ceramic applications as dispersing / deflocculating & viscosity reduction. These polymers work as primary deflocculating agent to reduce the viscosity and improve flowability of ceramic slurries.

PAAS can be adding in grinding process of clay to reduce the viscosity and stabilize the dispersed slurry for longer period.

Specification

| Parameter | Index | |

|---|---|---|

| Appearance | Colorless to pale yellow, clear liquid | Colorless to pale yellow, clear liquid |

| Total Solid (%) | 38 – 42 | 44 – 46 |

| Avg. Mol. Wt. (Aprx.) | 2000 | 4500 |

| Sp. Gravity | 1.25 – 1.35 | 1.3 – 1.4 |

| pH | 8 to 9 | 6 to 8 |

(These are typical values and not specifications)

Packing

Tanker Load, 1250 kg in IBC & 250 Kg barrels