Polymeric Dispersants for Paper Making

Paper Making

Acrylates are widely used in pigment and coating industry particularly in case of aqueous inorganic pigment slurries as primary dispersants. These polymers allow high pigment loading through their dispersing property and extended stability of pigment dispersion. So also, they find application in various paper making process like deinking, antiscalant in pulp making etc. We offer right quality product based on the application at reasonable price.

Synonyms : Polyacrylic Acid Sodium Salt (PAAS) 50%, Polyacrylate sodium, Sodium polyacrylate, aqueous dispersants, Carboxylate polymer, Copolymer of Maleic and Acrylic Acid (MA/AA), ACRYLIC ACID MALEIC ANHYDRIDE COPOLYMER, dispersants, maleic multipolymer, Viscosity reducing agent, water reducing agent, Ammonium polyacrylates.

Description

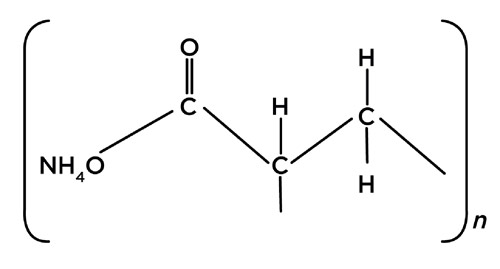

This is an ammonium salt of acrylic acid homopolymer having low mol. Wt. and narrow Mol. Wt distribution. The product being ammonium salt contribute to very small amt. of ash content upon ignition. Due to max. Organic content the product also leaves no or low pidding marks. Ammonium polyacrylate also shows good rubbing fastness is floor paints as compare to sodium salts.

Application

This polymer can be effectively used in coating pigment slurries of calcium carbonate, TiO2 particularly in paper coating. The product is also use as a primary dispersing agent in water born paint system for dispersion of pigments and extenders. It also finds application in pigment slurry making where high pigment loading is required the product reduces the viscosity of the pigment slurries in order to increase pigment loading.

Specification

| Parameter | Specification |

|---|---|

| Appearance | Colorless to pale yellow, clear liquid |

| Total Solid (%) | 44 – 46 |

| Avg. Mol. Wt. (Aprx.) | 4500 |

| Sp. Gravity | 1.15-1.25 |

| pH | 7 to 8 |

(These are typical values and not specifications)

Packing

Tanker Load, 1250 kg IBC & 250 kg barrel.

Description

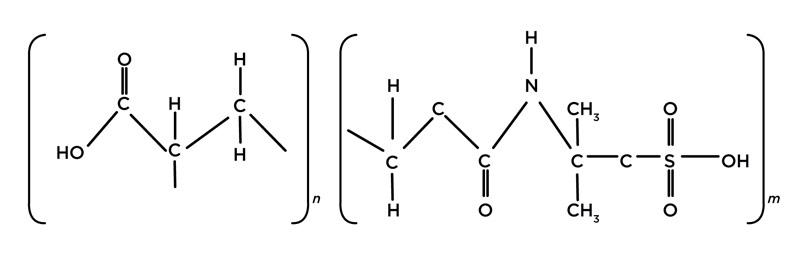

This is a low molecular weight carbxoylate sulphonated copolymer having high content of sulphonated group. This high content of sulphonated group creates strong anionic effect and provides high degree of water hardness tolerance to high the polymer. So also, due to this highly charged group the polymer gets stability in presence iron and can stabilize iron and phosphates.

Application

In paper making process calcium ion in pulp forms scales and pitting. Addition of the carboxylate sulphonated copolymer prevents the scale formulation through threshold inhibition effect and disperses the precipitated inorganic salts and other impurities through its high dispersing action. This can be effective use in cooking of pulp, recycling paper etc.

Specification

| Parameter | Specification |

|---|---|

| Appearance | Colorless to pale yellow, clear liquid |

| Total Solid (%) | 35 – 39 |

| Avg. Mol. Wt. (Aprx.) | 11000 |

| Sp. Gravity | 1.1 – 1.3 |

| pH | 4 to 5 |

(These are typical values and not specifications)

Packing

Tanker Load, 1250 kg IBC & 250 kg barrel.

Description

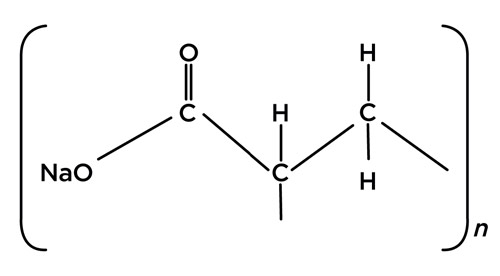

This is a low mol. Wt. acrylic acid homopolymer (Sodium salt) ideal for dispersing of inorganic pigments and extenders in water born systems. The polymer provides stable dispersion and control the viscosity of the system effectively.

Application

This polymer can be effectively used in coating pigment slurries of calcium carbonate, TiO2 particularly in paper coating. The product is also use as a primary dispersing agent in water born paint system for dispersion of pigments and extenders. It also finds application in pigment slurry making where high pigment loading is required the product reduces the viscosity of the pigment slurries in order to increase pigment loading.

Specification

| Parameter | Specification |

|---|---|

| Appearance | Colorless to pale yellow, clear liquid |

| Total Solid (%) | 44 – 46 |

| Avg. Mol. Wt. (Aprx.) | 4500 |

| Sp. Gravity | 1.15 – 1.25 |

| pH | 7 to 8 |

(These are typical values and not specifications)

Packing

Tanker Load, 1250 kg IBC & 250 kg barrel.